The metaverse either represents the next frontier of technology – or it’s already dead in the water. There is no between. At least, that’s what we’re led to believe if we read op-eds about the metaverse, which generally leave no room for nuance.

While the columnists sound off, real-world applications of metaverse technologies continue rolling off the production line. This week’s Hannover Fair (April 17-21) is a terrific case in point. The world’s leading trade fair for industry brings together 4,000 companies from the worlds of engineering and energy, all of them showcasing technological solutions for the 2020s and beyond.

Unsurprisingly, the metaverse and related technologies are well represented at this year’s event.

Metaverse at center of Industry 4.0

When the fair kicked off at the start of the week, one of the first topics on the agenda was – you guessed it – the metaverse.

Occupying the 10.35am slot was “Industrial Metaverse – Fact or Fiction? Vision, Technologies and Use Cases,” and that early event was a signpost of things to come: a number of panel discussions soon put the metaverse under the microscope, looking at the potential of virtual environments and ‘digital twins’ to boost productivity across industry.

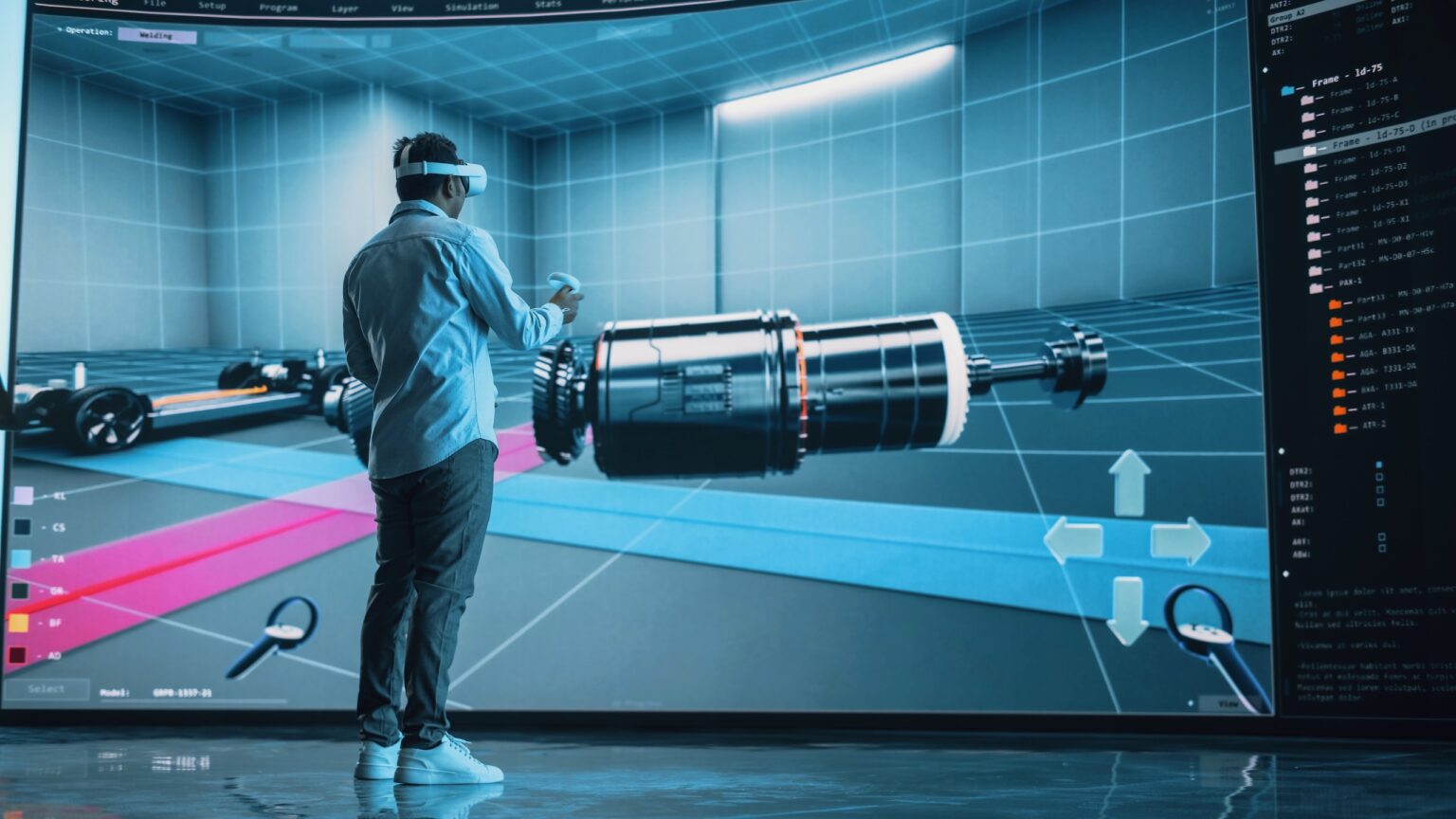

For Sebastian Klöß, who heads up the consumer technology division of digital industry association Bitkom, the VR-powered metaverse is “primarily about coupling machine data and real-time data from factories with the virtual world.”

Perhaps this is too simplistic a view, however. Others believe the metaverse will be a central pillar of Industry 4.0 or the Fourth Industrial Revolution, as it can integrate and augment other important technological touchstones – big data, artificial intelligence, cloud computing, manufacturing execution systems, et al.

A good example of this is Siemens’ new Digital Experience Center in Erlangen, Bavaria. Indeed, several representatives of the company including Head of Digital Experience Dominik Riehle are appearing at the fair to discuss the Center, which aims to “make the Siemens Digital Enterprise tangible and interactive,” principally by demonstrating virtually “the entire process chain from design to work preparation and production to shipping of a product.”

Digital twins are at the crux of the center: Siemens have created a technology that allows for the creation of holistic digital counterparts of logistics centers, furnishing industry with greater flexibility, higher throughput, and more sustainability.

Manufacturing is poised for digital twins.

Both for supply chains and physical production.

Example: Growth of search intent for qualifying supply chain terms pic.twitter.com/LHDKnv9y8H

— Robin Dechant (@robindchnt) April 11, 2023

As well as reducing the need for physical prototypes, digital twins give companies the chance to assess equipment in a safe virtual space before going into production.

According to Siemens, digital twins “allow the entire product lifecycle to be integrated with the factory lifecycle and performance data,” resulting in a “continuous open optimization loop for product and production.”

To demonstrate the potential of the tech, the company has built a digital twin of its own logistic center in Nuremberg, a facility that processes 12,000 orders and 22,000 delivery note items every day.

After talking up the Digital Experience Center in Hannover, the Siemens brass will head to next week’s LogiMAT, the International Trade Show for Intralogistics Solutions and Process Management, to do it all over again.

The metaverse ain’t dead

Elsewhere in Hannover, a company called DigitalTwin Technology is showcasing a product called Metaverse of Industrial Plant, wherein users “can explore a virtual world filled with industrial plants and facilities, complete with realistic graphics and sound effects.”

Another panel discussion will discuss how to harness industrial metaverse with robotics simulation and XR to accelerate time-to-market, while a ‘Future of Work’ summit considers the real-world applications of the metaverse in medium-sized industrial companies throughout Germany.

💡 @NeikeCedrik CEO of @siemensindustry announced that @Siemens, @nvidia, and @AWS would create the immersive #IndustrialMetaverse experience of @FREYRBattery gigafactory by combining real and digital worlds. https://t.co/3x3EsH9bby#HM23 #SIExHM @hannover_messe sponsored pic.twitter.com/f9kGFlJ6Gt

— Antonio Vieira Santos (@AkwyZ) April 17, 2023

Perhaps one of the most interesting exhibits is for Deutsche Post Subsidiary, which is using Microsoft’s mixed-reality HoloLens headset to showcase the design, build, operation, and optimization process of its e-Wave X electric vehicle.

A search for ‘metaverse’ on the Hannover Fair website generates 78 hits, 16 of which come under the Exhibitors & Products category and 59 under Speakers & Events.

Away from digital twins, there are many metaverse technologies on display at this year’s event – VR headsets and other wearables, digital design and scanning products, robots fitted with cameras that help create a virtual clone of a factory floor.

So, is the metaverse dead? It sure doesn’t sound like it.

and then

and then