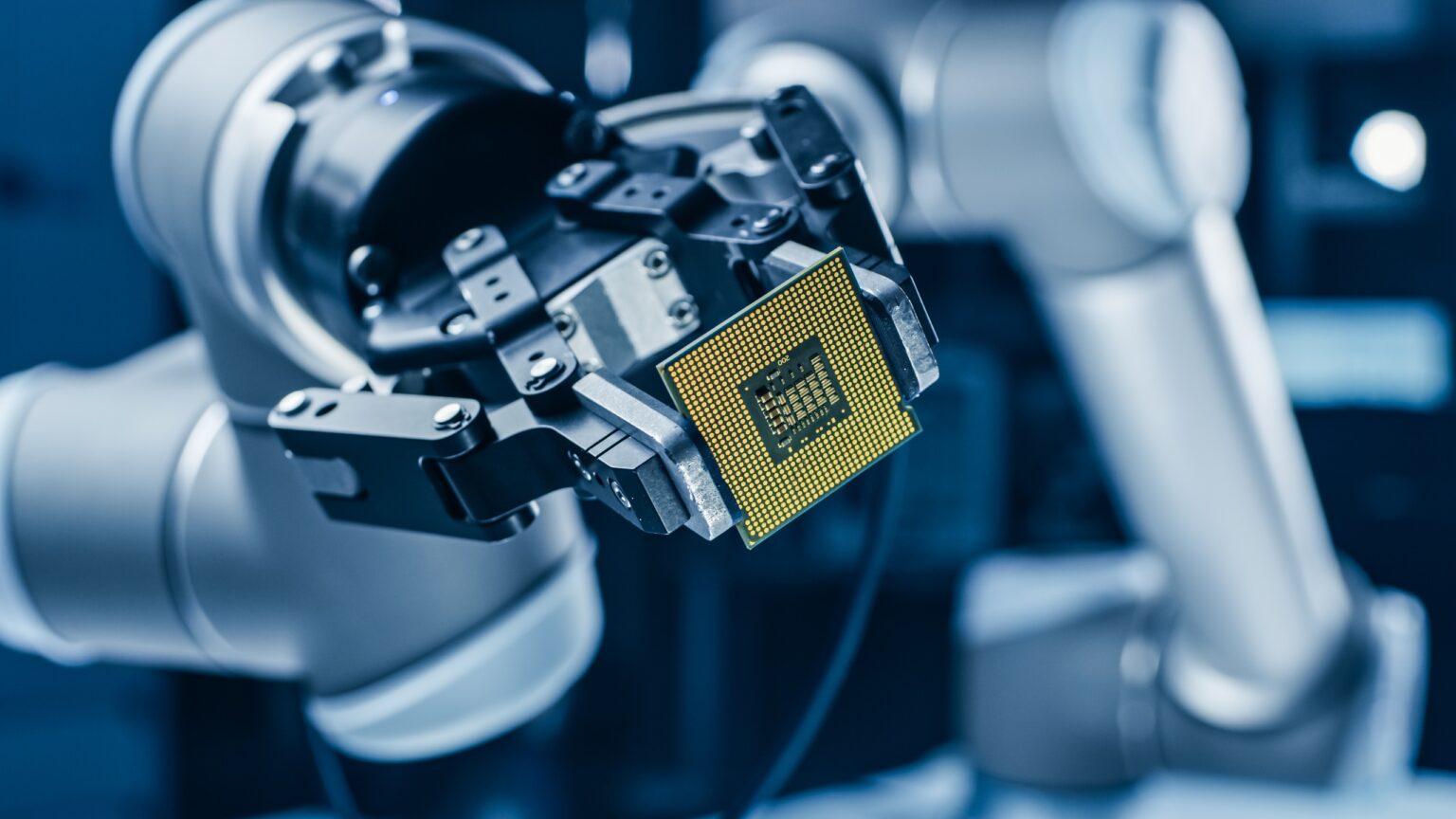

Samsung Electronics is building semi-conductor factories that are run completely by AI technology, eliminating the need for human labor on the production line, according to local media reports.

The South Korean chip maker has since started the development of an AI-powered system that uses so-called “smart sensors” to improve factory performance, the Asia Times reports.

Samsung will use the smart sensors to ‘control’ the manufacturing process, helping to cut costs and boost efficiency, it said. The goal is to have fully automated factories by 2030, free of human labor.

Also read: Samsung’s New AI Food and Recipe App Divides Opinion

AI upends job market

Samsung’s initiative comes as the tech industry has been hit with a wave of layoffs since the beginning of the year, as more and more companies replace staff with artificial intelligence.

Amazon, YouTube, Google, and others have all cut thousands of jobs in the last few weeks. Yet, in the case of Google, the company has simultaneously stepped up its AI-related hiring.

As MetaNews reported last week, Google offered select researchers at its AI arm DeepMind stock worth millions of dollars per person in a bid to retain its top talent amid interest from rival OpenAI.

The contrast demonstrates how AI has upended the job market as more companies turn toward automation and AI for operational and manufacturing purposes. Some studies predict that AI could lead to a loss of about 25% of all jobs over the next six years.

According to industry media, Samsung’s “smart sensing system” is designed to “monitor and analyze” the production process in real time, detecting defects and their causes. The manufacturing process is a top priority for the company’s AI plan, reports say.

Currently, smart sensors are reportedly able to automatically manage something that Samsung calls “plasma uniformity,” which is important for processes like deposition, etching, and cleaning.

The $390 billion conglomerate is also looking to wean itself from a dependence on foreign suppliers to in-house development in order to “gain control of the technology” and build relevant local expertise.

Samsung’s AI ambitions

Samsung is the world’s largest maker of memory chips, a type of computing hardware that focuses on recording information, such as RAM and solid-state drives (SSDs) made of NAND flash.

In 2023, the company revealed that it plans to use AI to optimize “integrated circuit design, material development, manufacturing, yield improvement, and packaging.” Those plans are now coming into play.

Samsung said that the AI-based technology will be applied both to its DRAM data-storage chips and NAND flash memory operations as well as to the firm’s contract manufacturing operations, the Asia Times wrote. The company is keen on catching up with Taiwan’s semiconductor giant TMSC and keeping America’s Intel at bay as chip sizes move from 3nm now to 2nm by 2025 and 1nm five years later.

As memory chips get smaller, the risk of defects that may be only detectable under a microscope becomes greater, something that could hamper production yields. Samsung believes AI will help to minimize the problem while “maintaining competitiveness.”

Shares of Samsung rose 1.4% to 74,000 won (US~$55) on Monday on the Korean Stock Exchange, according to Yahoo Finance. In the three months to December 2023, Samsung’s operating profit fell 35% year-on-year to 2.8 trillion won ($2.1 billion). This was an improvement from the 78% annual decline in the previous quarter.

and then

and then