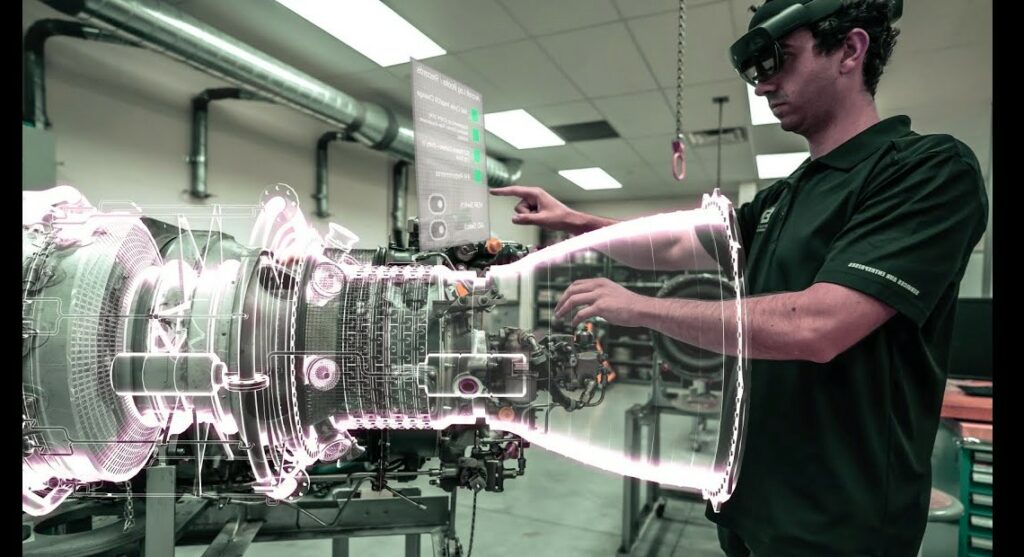

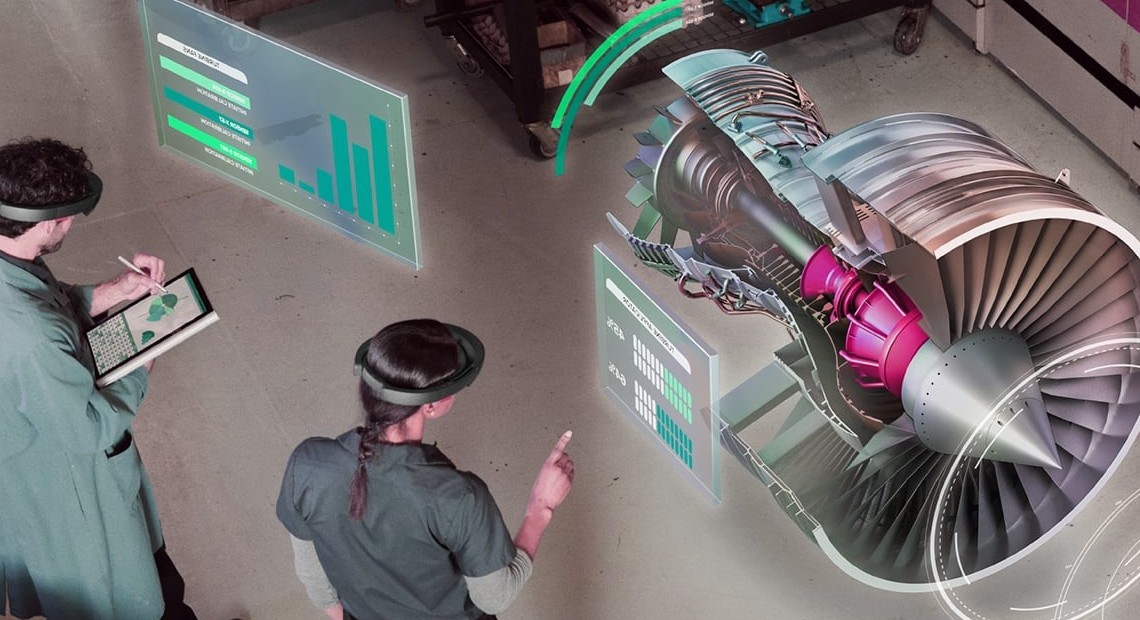

Boeing Co’s factory of the future, immersive 3-D engineering designs will be twinned with robots that speak to each other. The $3,500 HoloLens headsets made by Microsoft will connect mechanics around the world in the meantime.

It’s a taste of a bold new Boeing strategy to bring together huge design, production. And airline services activities under a single digital ecosystem in as little as two years.

Boeing is entering 2022 fighting to reassert its engineering dominance after the 737 MAX crisis

After the 737 MAX debacle, the planemaker is battling to reclaim its engineering dominance in 2022. While also setting the groundwork for a future aircraft program over the next decade – a $15 billion risk. It also hopes to avoid future production issues. Including as the structural defects that have plagued its 787 Dreamliner in recent months.

The necessity to deliver on growing order books has opened up a new front in Boeing’s conflict with Europe’s Airbus. This time on the production floor, after years of fierce market competition.

Boeing’s approach has so far been characterized by incremental advancements inside single aircraft programs or tooling. Rather than the systemic overhaul that Hyslop is pushing for now.

Both airline titans’ simultaneous endeavor is symptomatic of a global digital revolution, as manufacturers like Ford Motor Co and social media businesses like Facebook parent Meta Platforms Inc shift work and play into an immersive virtual world known as the metaverse.

So how does the metaverse work in aviation?

Boeing’s holy grail for its next new aircraft, like Airbus’s, is to create and link virtual three-dimensional “digital twin” reproductions of the plane with a production system that can perform simulations.

In addition to the digital mockups, a “digital thread” relates every piece of information about the plane from its conception. From airline needs to millions of parts to thousands of pages of certification documentation – and reaches all the way down the supply chain.

Overhauling antiquated paper-based practices could bring powerful change.

Hyslop says that more than 70% of quality concerns at Boeing stem from design flaws. Such tools, according to Boeing, will be critical in getting a new airplane from concept to market in as little as four or five years.

“You’ll get greater speed, better quality, better communication, and better reactivity when problems arise,” Hyslop added.

“By improving the quality of the supplier base and by making the airplane build more seamless and minimizing rework, the financial performance will go up.”

and then

and then